MILPRF50884F

APPENDIX A

A.3.6.2 Conductor pattern.

A.3.6.2.1 Conductor finish. A conductor finish plating or coating material shall be used that enables the printed

wiring board to meet all of the performance requirements of this specification. Unless otherwise specified (see

A.3.1.1), the following conductor finish condition requirements shall apply.

A.3.6.2.1.1 Dewetting. For tin alloys, reflowed tin-lead, or solder coated surfaces, a maximum of 5 percent of

dewetting is permitted on any conductive surface where a solder connection will be required. Dewetting on

conductors, ground, or voltage planes not used for solder connections shall meet the requirements of JSTD003.

A.3.6.2.1.2 Nonwetting. For tin alloys, reflowed tin-lead, solder coated surfaces, nonwetting is not permitted on

any conductive surface where a solder connection will be required. Absence of solder on the vertical sides of lands

shall be acceptable.

A.3.6.2.1.3 Outgrowth and overhang. There shall be no outgrowth on the conductor edges when finished with

fused tin-lead or solder coating. The maximum permissible outgrowth on conductor edges finished with surface finish

metals other than tin-lead or solder shall be .001 inch (0.025 mm).

A.3.6.2.1.4 Protective finishes for internal metal cores or metal backing. The plating, coating, or surface treatment

type and thickness of internal metal cores and metal backing materials shall be as specified (see A.3.1.1).

A.3.6.2.1.5 Thickness (plating or coating). The conductor finish plating or coating thickness shall be as specified

(see A.3.1.1). If not specified on the applicable master drawing, the minimum conductor finish plating or coating

thickness should not be less than the values specified in the IPC's 2220 series of documents for the design of flexible

or rigid-flex printed wiring boards. On the date of publication of this document, those values are reproduced in table

AI. (Also see A.3.5.2.5).

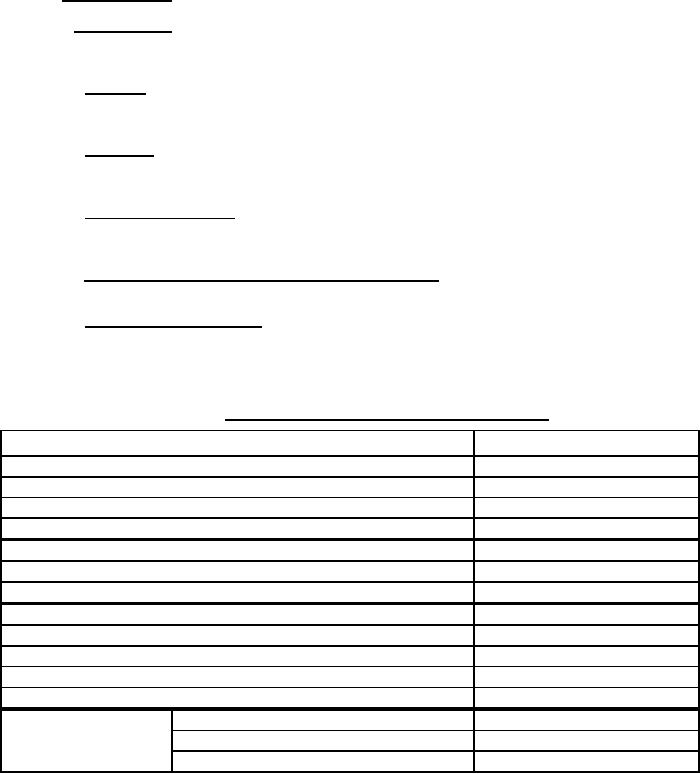

TABLE AI. Conductor surface finish plating and coating thickness.

Material

Thickness, in inches (mm)

Gold (electroplated) for edge-board contacts and areas not to be soldered

.00005 (0.0013 mm) minimum

Gold (electroplated) for areas to be soldered

.000018 (0.00046 mm) maximum

Gold (electroplated) for areas to be wire bonded, ultrasonic

.000002 (0.00005 mm) minimum

Gold (electroplated) for areas to be wire bonded, thermosonic

.00003 (0.0008 mm) minimum

Nickel (electroplated); under gold areas to be wire bonded

.00012 (0.003 mm) minimum

Nickel (electroplated); edge-board contacts

.00008 (0.002 mm) minimum

Nickel (electroplated); barrier to prevent formation of Cu-Sn compounds

.00005 (0.0013 mm) minimum

Organic solderability preservative (OSP)

Solderable

Immersion silver

Solderable

Electrodeposited tin-lead, fused or solder coat

Coverage and solderable

Electrodeposited tin-lead, unfused

.0003 (0.008 mm) minimum

Solder coat over base copper

Coverage and solderable

Electroless nickel

.00012 (0.003 mm) minimum

ENIG

Immersion gold (areas not to be soldered)

.000002 (0.00005 mm) minimum

Immersion gold (areas to be soldered)

Solderable

25

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business