MILPRF50884F

APPENDIX A

A.6.3.2 Qualification expiration and Qualified Products Database (QPD) 50884. Qualification listings within

QPD50884 for manufacturers qualified under this appendix (QPL product assurance level) includes the qualification

expiration date as the last six digits of the test reference number. This date, formatted as (month/day/year), is the

actual qualification expiration date for that listing. This date signifies that the company is no longer qualified (unless

notified in writing by the qualifying activity) whether or not that individual listing has been removed the QPD. If the

company has not requalified before the next issue of the QPD is published, then the listing will not be included on the

QPD.

A.6.4 Ionic contamination testing (surface cleanliness). The values of ionic contamination specified in this

document were established in the late 1970 s by the U.S. Navy with the issuance of the Naval Air Center Materials

Research Report No. 378. The values used in the report were eventually used in the canceled specification

MILP28809 as a baseline needed for completed assemblies. The chemistries of the fluxes and cleaning solutions

used in the 1970 s were very different than what is used currently. If levels of ionic contamination that are needed for

today s circuit card assemblies may be well below that threshold established in Naval Air Center Materials Research

Report No. 378 or allowed by this specification.

A.6.4.1 Flux removal. Selection of procedures for flux removal is at the manufacturer's discretion. A procedure

should be chosen which will enable the printed wiring board fabricator to produce results enabling compliance with

this document. Both polar and nonpolar solvents may be required to effect adequate flux removal.

A.6.4.2 Alternate methods and equipment. The following methods of determining the cleanliness of printed wiring

boards have been shown to be equivalent to the sodium chloride equivalent ionic contamination test method:

a.

The Kenco Alloy and Chemical Company, Incorporated, "Omega Meter, Model 200" (see

b.

Alpha Metals Incorporated, "Ionograph" (see https://www.scscoatings.com).

c.

Zero Systems, Incorporated, "Zero Ion, Model ZI100."

d.

Westek, "ICOM 5000."

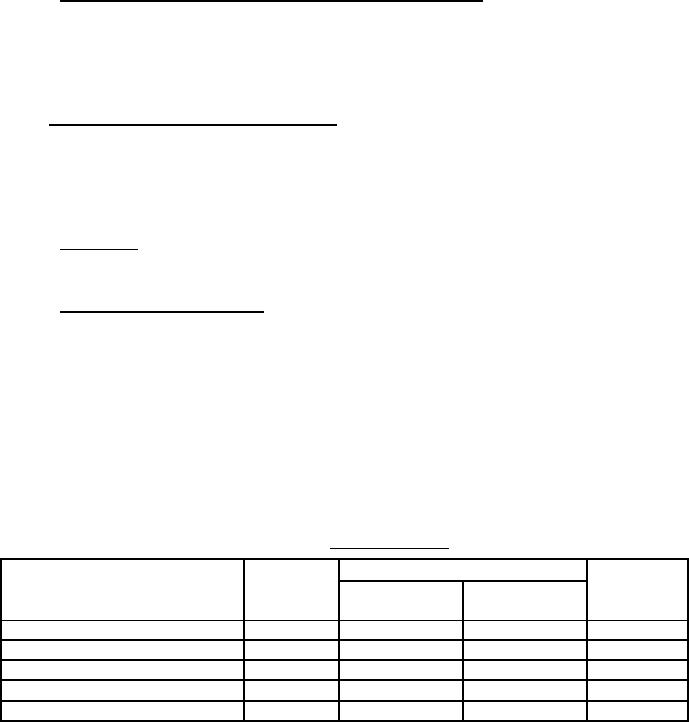

Table AXII list the equivalence factors for these methods in terms of micrograms equivalents of sodium chloride for

each unit area.

TABLE AXI. Equivalence factors.

Equivalents of sodium chloride

Related

Equivalence

Method

factors

Micrograms per

Micrograms per

test method

square inch

square cm

Resistivity of solvent extract

1.00

10.06

1.56

2.3.25

1.39

14.00

2.20

2.3.25

Omega Meter

2.01

20.00

3.10

2.3.25

Ionograph

3.68

37.00

5.80

N/A

Zero Ion

2.20

22.00

3.40

N/A

ICOM 5000

56

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business