MILPRF50884F

APPENDIX A

A.3.6.3.2 Etchback (when specified, see A.3.1.1) (see figures G9 and G10). When specified (see A.3.1.1),

holes that will be plated shall be processed for the lateral removal of resin and reinforcement material (woven glass or

other media) from the internal conductors prior to plating. Unless otherwise specified (see A.3.1.1), etchback shall be

a minimum of .0001 inch (0.0025 mm) and no greater than the specified minimum internal annular ring or .002 inch

(0.05 mm), whichever is less, with a preferred depth of .0005 inch (0.013 mm) when measured at the internal copper

contact area protrusion (see figure G9). The etchback shall be effective on at least the top or bottom (or both)

surface of each internal conductor to provide at least a two (2) point contact with the subsequent hole plating (see

figure G10). Negative etchback is not acceptable when etchback is specified. Wicking shall meet the requirements

of A.3.6.6.

A.3.6.4 Plated-through hole plating. Unless otherwise specified (see A.3.1.1), copper plating thickness applies to

the hole wall, the hole knee, and the surface land of the plated-through hole (see figures G11, G12 and G13).

A.3.6.4.1 Copper plating thickness (when applicable) (see figures G11, G12 and G13). The copper plating

thickness (on the surface, in plated-through holes, in blind and buried vias) shall be as specified (see A.3.1.1). If not

specified on the master drawing, the minimum copper plating thickness should not be less than the values specified

in the IPC's 2220 series of documents for the design of flexible or rigid-flex printed wiring boards. On the date of

publication of this document, those values are reproduced in tableAIV for plated through holes and table AV for

blind and buried vias.

A.3.6.4.2 Wrap copper plating (see figures G12 and G13). Unless otherwise specified, the wrap plating (plated

through hole surface and knee continuous copper plating) thickness shall be as specified (see 1.2.6). The wrap

plating shall not be reduced by more than 20 percent for grade A, 50 percent for grade B, and 80 percent for grade C

of the specified wrap copper plating thickness due to planarization or other processing.

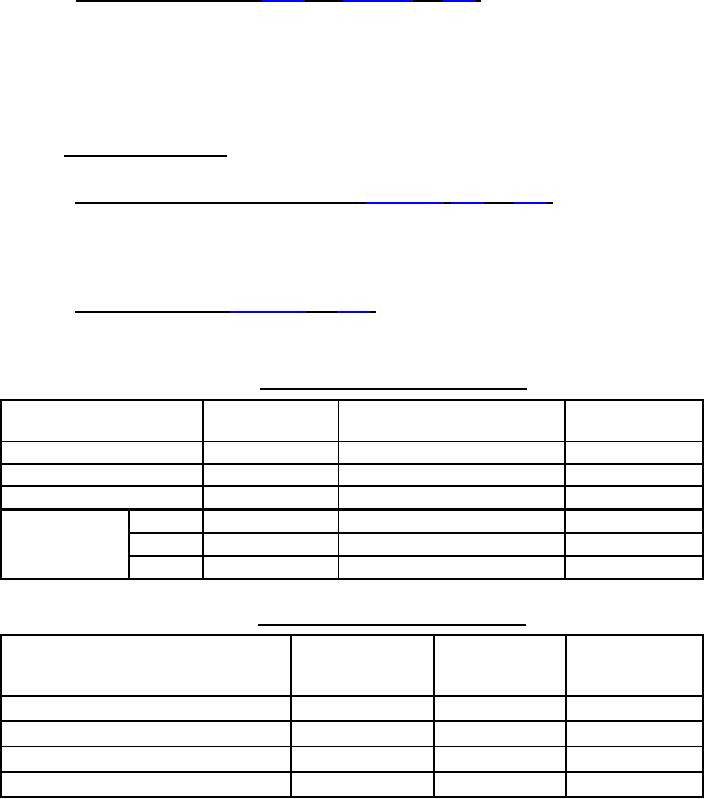

TABLE AIV. Plated-through hole copper plating thickness.

Plating

Type 2

Types 2, 3 and 4

Types 3 and 4

inch

(mm)

inch

(mm)

inch

(mm)

Overall board thickness

≤ .008

(0.2)

> .008 and ≤ .030

(0.2 and 0.76)

>.030

(0.76)

.001

(0.025)

.0014

(0.035)

Minimum average

.0005

(0.013)

.0008

(0.020)

.0012

(0.030)

Minimum thin area

.0004

(0.010)

Minimum wrap

Grade A

.0004

(0.010)

.0004

(0.010)

.00056

(0.014)

copper plating

Grade B

.00025

(0.006)

.00025

(0.006)

.00035

(0.009)

after all

Grade C

.0001

(0.0025)

.0001

(0.0025)

.00014

(0.0036)

processing

TABLE AV. Blind and buried via copper plating thickness.

Minimum average

Minimum thin area

Minimum wrap

Via design characteristic

copper plating

inch (mm)

inch (mm)

inch (mm)

Blind vias

.001

(0.025)

.0008 (0.020)

.0003

(0.008)

Microvias, blind and buried

.0005 (0.013)

.0004 (0.010)

.00025 (0.006)

Buried vias, single layer core

.0006 (0.015)

.0005 (0.013)

.0003

(0.008)

Buried vias, core greater than 2 layers thick

.001

(0.025)

.0008 (0.020)

.0005

(0.013)

28

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business