MILPRF50884F

APPENDIX A

A.4.7.2.4 Noncompliance. If one or more sample units fail to pass group C inspection, the manufacturer shall

notify the qualifying activity of such failure within 3 business days. The manufacturer shall take corrective action on

the materials or processes, or both, as warranted, and on all units of product which can be corrected and which were

manufactured under essentially the same conditions (materials, processes, and equipment) and which are

considered subject to the same failure. If the lot or lots directly represented by the group C failure have been

shipped, the manufacturer shall notify the acquiring activity of the failure and shall recall the affected lot or lots for

reinspection, if possible. All other lots represented by extension of qualification by the failed group C sample are

considered noncompliant until a sample passes group C inspection. Group A inspection and shipment of the product

shall be discontinued until corrective action, acceptable to the qualifying activity, has been taken. After the corrective

action has been taken, group C inspection shall be repeated on additional sample units (all inspections, or the

inspection which the original sample failed, at the discretion of the qualifying activity). Group A inspection may be

reinstituted; however, final acceptance and shipment shall be withheld until the group C inspection has shown that

the corrective action was successful.

A.4.7.2.5 Disposition of sample units. Sample units which have been subjected to group C shall be retained as

specified in A.3.9.

A.4.8 Methods of inspection. The following verification tests and test methods assure printed wiring board integrity

within typical operating conditions and applications. Alternate methods are allowed with prior approval by the

qualifying activity. The test methods described herein are the preferred methods and shall be the referee method in

case of dispute when alternate test methods result in differing or conflicting results.

A.4.8.1 Visual and dimensional inspection. The visual and dimensional features of the printed wiring board test

specimen shall be inspected using either test method number 2.2.1 or 2.2.2 of IPCTM650, as applicable. Unless

otherwise specified, the magnifications in table AX shall be used for the conductor width or land diameter/width of

features under inspection. Referee inspection needed to confirm a suspected defect of the specimen features shall

be accomplished at a magnification of up to 40X, as applicable to confirm the suspected defect. Characteristics not

observable through solder mask shall be evaluated prior to its application to the surface of the printed wiring board

(see A.4.6.1). Verification of printed wiring board dimensional parameters using automated inspection technology

(AOI and AXI) shall be acceptable.

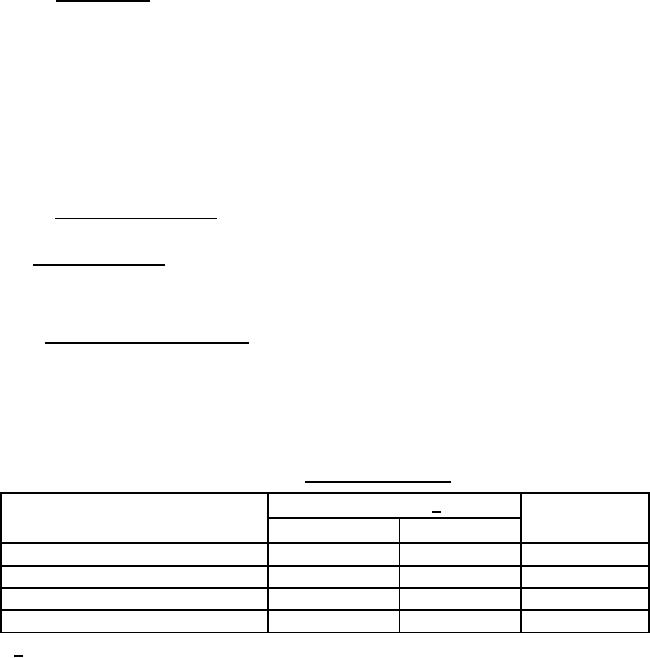

TABLE AX. Inspection magnification.

Magnification 1/

Conductor width or land diameter/width

IPCOI645 grade

Standard inspection

Referee inspection

Greater than .04 inches (1.0 mm)

1.75 x

4x

IV & V

From .02 to .04 inches (0.5 to 1.0 mm)

4x

10x

V & VI

From .001 to .02 inches (0.025 to 0.5 mm)

10x

20x

VI & VII

Less than .001 inches (0.025 mm)

20x

40x

VII & VIII

1/

Referee conditions are used to verify printed wiring boards rejected at the standard inspection

magnification power. For printed wiring board designs with mixed conductor and land diameters

and widths, the greater magnification power may be used for the inspection of the entire printed

wiring board.

46

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business