MIL-DTL-62740A(AT)

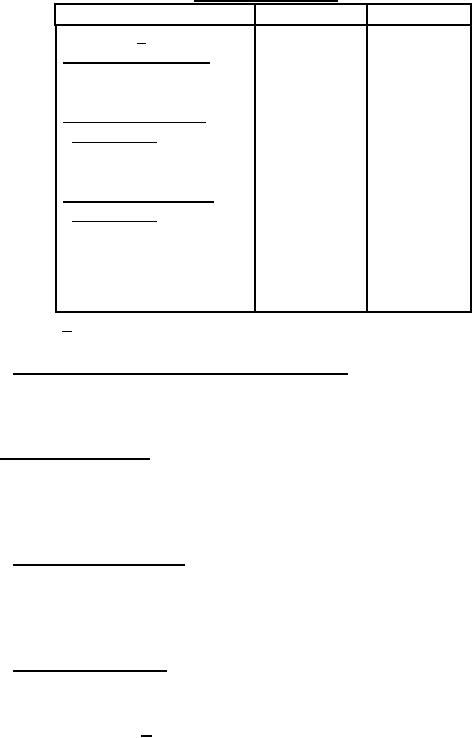

TABLE IV. Verification method - Continued.

Title

Requirement

Verification

ATE Test 1/

3.3.17

4.2.3.17

Interface requirements:

3.4

4.2.4

Overall envelope &

3.4.1

4.2.4.1

interfaces

Ownership & support

4.2.5

3.5

requirements

Interchangeability

4.2.5.1

3.5.1

Identification marking

4.2.5.2

3.5.2

Operating environment

4.2.6

3.6

requirements

Temperature

3.6.1

4.2.6.1

Fungus

3.6.2

4.2.6.2

Shock

3.6.3

4.2.6.3

Vibration

3.6.4

4.2.6.4

1/ Not required unless specified (see 6.2).

4.1.2 Conformance Inspection (CI) 100% inspection. CI shall be conducted on all items

(100% inspection) and shall include those examinations and tests from table IV as specified in the

contract.

4.2 Verification methods. Acceptable verification methods included in this section are

visual inspection, measurement, sample tests, full-scale demonstration tests, simulation, modeling,

engineering evaluation, component properties analysis, and similarity to previously-approved or

previously-qualified designs.

4.2.1 Verification alternatives. The manufacturer may propose alternative test methods,

techniques, or equipment, including the application of statistical process control, tool control, or

cost effective sampling procedures to verify performance. See the contract for alternatives that

replace verification methods required by this specification.

4.2.2 Inspection conditions. Unless otherwise specified herein, all inspections shall be

performed under the following standard (room) ambient conditions:

a. Temperature 77 + 18°F.

b. Relative humidity: Uncontrolled room ambient.

c. Atmospheric pressure: Site pressure.

10

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business