MILPRF55110G

6.5.3

6.5.3 Printed wiring board types. The printed wiring board types should be as specified herein.

6.5.3.1

6.5.3.1 Type 1. Type 1 rigid printed wiring boards have only one conductive layer (singlesided conductor pattern)

with cover lay and no plating in the component holes.

6.5.3.2

6.5.3.2 Type 2. Type 2 rigid printed wiring boards are printed wiring boards with conductor patterns on both sides

of the printed board (doublesided). In addition, the design of the printed wiring board may require plated-through

holes in order to connect the conductor patterns on both sides together.

6.5.3.3

6.5.3.3 Type 3. Type 3 rigid printed wiring boards are multilayered (with 3 or more conductor layers) with plated

holes. Type 3 designs include those with metal core and blind or buried via holes.

6.5.4

6.5.4 Product assurance. The method of complying with the two different levels of this specification using either

the QPL method that has been integral to this specification since revision MIL-P-55110D or the newer method,

QPL/QML which was introduced in revision MIL-PRF-55110F.

6.5.4.1

6.5.4.1 QML. A list of manufacturers, by name and plant address, who have met the certification and qualification

requirements stated in MIL-PRF-31032. A QML focuses on qualifying an envelope of materials and processes rather

than individual products or designs. That envelope is qualified by carefully selecting representative worst case test

vehicles or representative samples from production that contain all potential combinations of materials and processes

that may be subsequently used during production. A QML is normally appropriate for items of supply that have very

rapid technological advancement or a myriad of variations or custom designs that make individual product

qualifications impractical or excessively expensive.

6.5.4.2

6.5.4.2 QPL. A QPL focuses on qualifying individual products or families of products. A QPL will normally be

appropriate for items of supply that are stable and will be continually available for extended period of time.

6.5.4.3

6.5.4.3 QPL/QML. A transitional program that allows a manufacturer that is certified and qualified to the QML

program of MIL-PRF-31032 to fabricate, test, and supply products to this specification.

6.5.5

6.5.5 QPL product assurance procedures. The product assurance procedures includes all associated

documentation that is used by the manufacturer in order to comply with the requirements of this specification.

6.6

6.6 Environmentally preferable materials. Environmentally preferable materials should be used to the maximum

extent possible that the material meets or exceeds the operational and maintenance requirements, and promotes

economically advantageous life cycle costs. Table I lists the Environmental Protection Agency's (EPA) top 17

hazardous materials targeted for major usage reduction. If any of these hazardous materials are required, it is

recommended that it be used only when other materials cannot meet performance requirements.

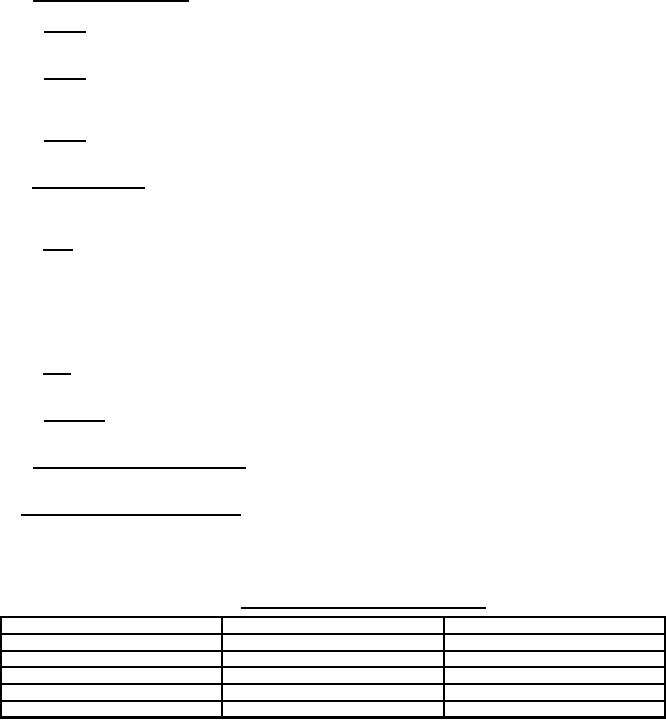

TABLE I

TABLE I. EPA top seventeen hazardous materials.

Benzene

Dichloromethane

Tetrachloroethylene

Cadmium and compounds

Lead and compounds

Toluene

Carbon Tetrachloride

Mercury and compounds

1,1,1 Trichloroethane

Chloroform

Methyl Ethyl Ketone

Trichloroethylene

Chromium and compounds

Methyl Isobutyl Ketone

Xylenes

Cyanide and compounds

Nickel and compounds

7

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business