MILPRF55110G

APPENDIX A

A.6.3

A.6.3 Qualification master drawings. Although the qualification test specimen master drawings IPC-100041,

IPC-100042, IPC-100043, and IPC-100044 specified in A.2.1.1 specifies the use of rigid base materials compliant to

MIL-P-13949, manufacturer's can qualify using base material by specifying the base material on the application for

qualification. In addition, the zone C (except for the external conductor traces on test coupon E5) of the qualification

master drawing is required to be present on the qualification test specimen and is to be examined during qualification

testing.

A.6.3.1

A.6.3.1 Transference of qualification. Manufacturers currently qualified to MIL-PRF-55110F will have their

qualification transferred to this document. The expiration date of their current qualification will not be changed.

Qualifications in process (before the date of this document) will be performed to the requirements MIL-PRF-55110F

with amendment 1. New applications for qualification (after the date of this document) will be performed to the

requirements of this revision.

A.6.3.2

A.6.3.2 Qualification expiration and QPL-55110. Qualification listings within QPL-55110 for manufacturers

qualified under this appendix (QPL product assurance level) includes the qualification expiration date as the last six

digits of the test reference number. This date, formatted as (month/day/year), is the actual qualification expiration

date for that listing. This date signifies that the company is no longer qualified (unless notified in writing by the

qualifying activity) whether or not that individual listing has been removed the QPL. If the company has not requalified

before the next issue of the QPL is published, then the listing will not be included on the updated QPL.

A.6.4

A.6.4 Cleanliness, alternate methods. The following methods of determining the cleanliness of printed wiring

boards have been shown to be equivalent to the resistance of solvent extract test method:

The Kenco Alloy and Chemical Company, Incorporated, "Omega MeterTM, Model 200."

a.

Alpha Metals Incorporated, "IonographTM" (see URL: https://www.scscookson.com).

b.

Zero Systems, Incorporated, "Zero IonTM, Model ZI100"(see URL: https://www.aqueoustech.com).

c.

Westek, "ICOM 5000TM."

d.

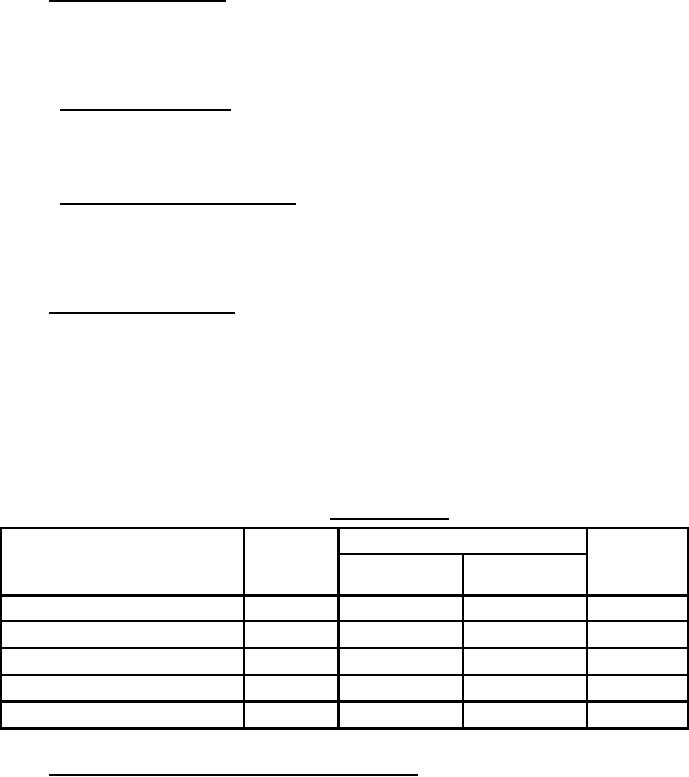

Table AVI lists the equivalence factors for these methods in terms of microgram equivalents of sodium chloride per

unit area. table A-VI TABLE AVI

TABLE AVI. Equivalence factors.

Equivalents of sodium chloride

Related

Method

Equivalence

IPC-TM-650

Micrograms per

Micrograms per

factors

test method

square inch

square cm

Resistance of solvent extract (ROSE)

1.00

10.06

1.56

2.3.25

Omega meterTM

1.39

14.00

2.20

2.3.25

IonographTM

2.01

20.00

3.10

2.3.25

Zero ionTM

3.68

37.00

5.80

N/A

ICOM 5000TM

2.20

22.00

3.40

N/A

A.6.5

A.6.5 Certified suitable laboratories (acceptable to the Government). Government accepted test laboratories are

those facilities (either internal to the QPL manufacturer or a separate independent laboratory) that have demonstrated

their ability to perform the verification test required by this document. A list of laboratories that have been certified is

available at https://www.dscc.dla.mil/offices/sourcing_and_qualification. Search for a document titled "PWB

40

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business