MILPRF55110G

APPENDIX E

E.3

E.3. DEFINITIONS

E.3.1

E.3.1 Sequential Electrochemical Reduction Analysis (SERA). A chronopotentiometric reduction method for

assessing tin-lead finish solderability.

E.4

E.4. TESTING

E.4.1

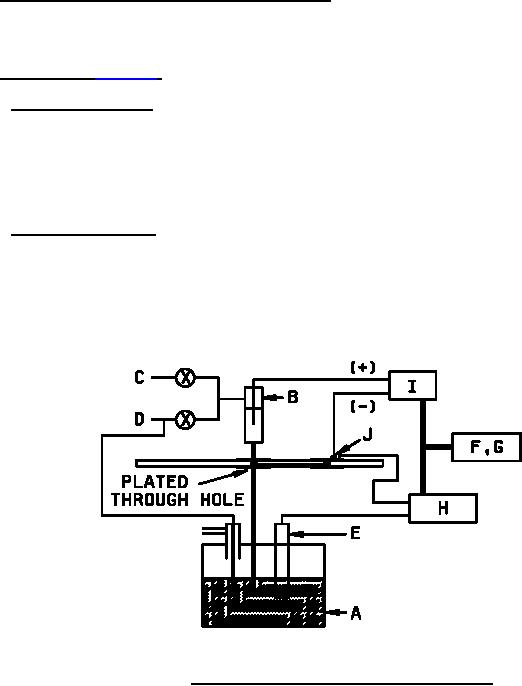

E.4.1 Apparatus (see figure E1).

E.4.1.1

E.4.1.1 Reservoir (see detail A). The reservoir shall be a container constructed of a nonmetallic, nonreactive

material with a minimum volume of 500 ml. The reservoir shall have an inlet/outlet port, test head chamber port, and

a saturated calomel electrode (SCE) reference electrode port. The inlet/outlet port shall be connected to a vacuum

trap tube. The inlet/outlet port shall incorporate a diffuser to aid in the effectiveness of the inert gas purging.

Polypropylene tubing may be used for connection tubing. All connection fittings shall be of a nonreactive material.

The reservoir shall have the capability of maintaining a positive pressure environment. The reservoir shall be emptied

and rinsed with deionized water for every 16 hours of testing.

E.4.1.2

E.4.1.2 Test head (see detail B). The test head shall be constructed of a nonmetallic, nonreactive material. The

test head shall have ports to allow inert gas purging and intake/expulsion of borate buffer solution. The test head

shall have either an optical or mechanical means of aligning the test head chamber over the test plated-through hole.

The test head shall use Vitron or equivalent o-rings for the test head to test surface interface seals. These o-rings

shall be replaced after every 8 hours of testing unless integrity of the o-rings can be documented for extended

periods. The test head shall have the capability of maintaining a positive pressure environment.

figure E-1 FIGURE E1

FIGURE E1. Schematic of SERA plated through hole apparatus.

68

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business