MIL-DTL-62741A(AT)

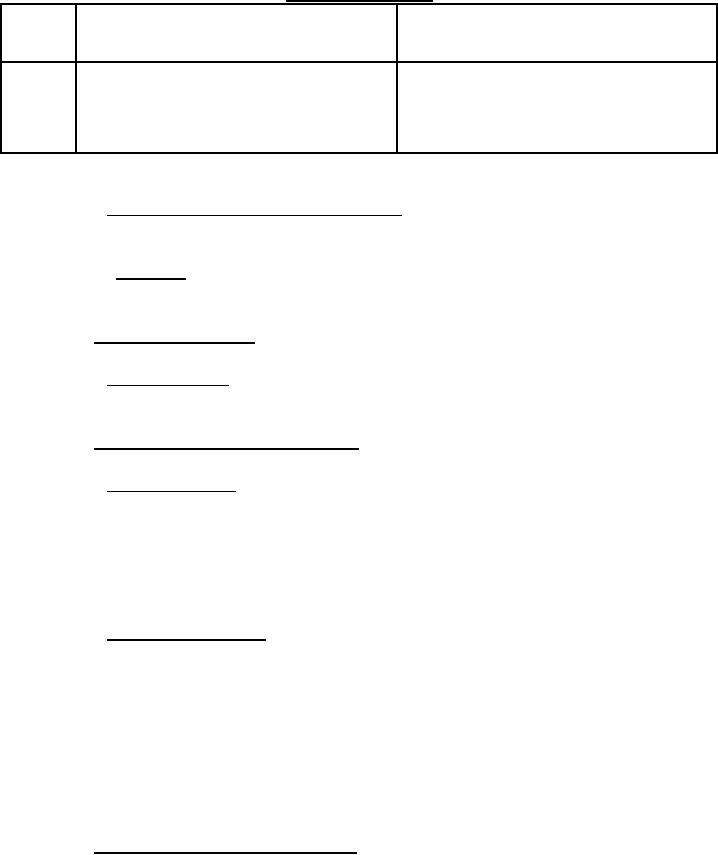

TABLE VI. ADCON conversion - Continued.

ADCON MSB

ADCON LSB

BUS

BUS

Input

voltage

7

6

5

4

3

2

1

0

7

6

5

4

3

2

1

0

-3.000 V

0

X

1

X

0

1

0

0

1

1

0

0

1

1

0

0

-3.500 V

0

X

1

X

0

1

0

1

1

0

0

1

1

0

0

1

-4.000 V

0

X

1

X

0

1

1

0

0

1

1

0

0

1

0

1

-4.500 V

0

X

1

X

0

1

1

1

0

0

1

1

0

0

1

0

-4.999 V

0

X

1

X

0

1

1

1

1

1

1

1

1

1

1

0

(X denotes a don't care condition.)

3.3.9 Automated testing equipment (ATE) test. The PWA shall pass TACOM approved

ATE test installed in TACOM approved ATE or equivalent.

3.3.10 Soldering. Soldering shall meet or exceed the requirements of

ANSI/IPC J-STD-001 (see 4.2).

3.4 Interface requirements. Each PWA shall accommodate the following requirements.

3.4.1 Overall envelope. Overall envelope of the PWA shall be in accordance with

drawing 12258777.

3.5 Ownership and support requirements.

3.5.1 Interchangeability. Interchangeability tolerances should permit parts, subassemblies

and assemblies to be used in their parent assemblies without regard to the source of supply or

manufacturer. Parts, subassemblies, and assemblies having the full range of dimensions and

characteristics permitted by the specification governing the part, subassembly or assembly should

be usable as replacement items without selection and without departure from the specified

performance guidelines of the parent items.

3.5.2 Identification marking. Unless otherwise specified (see 6.2), identification marking

shall be permanent and legible and shall include as a minimum the following:

a.

Nomenclature "PRINTED WIRING ASSEMBLY, MUX/ADCON".

b.

Military part number.

c.

Manufacturer's cage code and name

d.

Manufacturer's serial number.

e.

Contract number.

f.

Symbol "US".

3.6 Operating environment requirements. Each PWA shall operate under the following

environmental conditions without damage or loss of performance.

8

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business