MIL-PRF-31032/1B

*

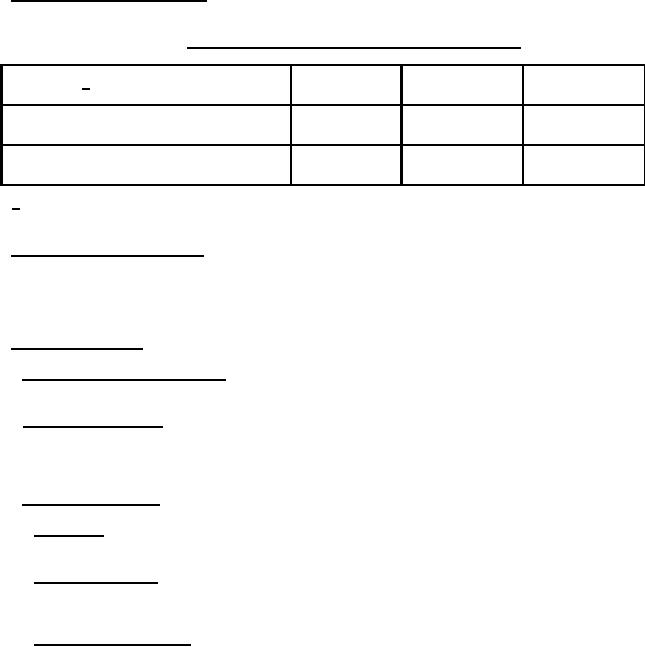

4.5 Periodic conformance inspection. Periodic conformance inspection shall be in accordance with TRB approved

periodic conformance inspection plan or table II herein.

*

TABLE II. Periodic conformance inspection baseline test coverage.

Requirement

Method

Frequency

Inspection 1/

paragraph

paragraph

Elongation

3.7.3.2.1

4.7.3.2

Monthly

Tensile strength

3.7.3.2.2

4.7.3.3

Monthly

Rework simulation

3.7.4.5

4.7.4.5

Monthly

Moisture and insulation resistance

3.7.6.1

4.7.6.1

Monthly

*

1/

A minimum of two test specimens per inspection.

*

4.6 Capability verification inspection. Capability verification inspection shall be in accordance with the TRB

approved capability verification inspection plan. The frequency of this verification shall be as a minimum every 2

years. Each base material type qualified shall be verified. The following tests and inspections should be considered

when accomplishing capability verification inspection: thermal shock, rework simulation, and moisture and insulation

resistance testing.

4.7 Methods of inspection.

4.7.1 Visual and dimensional inspection. The printed board specimen shall be inspected in accordance with test

method number 2.1.8 of IPC-TM-650, except that the magnification shall be 1.75x (3 diopters), minimum.

*

4.7.2 Microsection inspection. Microsection inspections shall be accomplished by using methods in accordance

with either test method number 2.1.1 or 2.1.1.2 of IPC-TM-650. The plated-through holes shall be microsectioned in

the vertical plane with an accuracy of +/- 10 percent of the center of the hole. A minimum of three holes shall be

evaluated per microsection.

4.7.3 Chemical test methods.

*

4.7.3.1 Cleanliness. The printed board specimen shall be inspected for ionic cleanliness in accordance with test

method number 2.3.25 of IPC-TM-650.

*

4.7.3.2 Elongation of copper. The test for elongation of copper shall be performed in accordance with ASTM E345

or test method number 2.4.18.1 of IPC-TM-650. The travel speed of testing shall be 50.0 mm ± 1.0 mm (1.97 ± .03

inches) per minute.

*

4.7.3.3 Tensile strength of copper. The test for tensile strength of copper shall be performed in accordance with

ASTM E345 or test method number 2.4.18.1 of IPC-TM-650. The travel speed of testing shall be 50.0 mm ± 1.0 mm

(1.97 ± .03 inches) per minute.

12

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business