MILPRF55110G

APPENDIX C

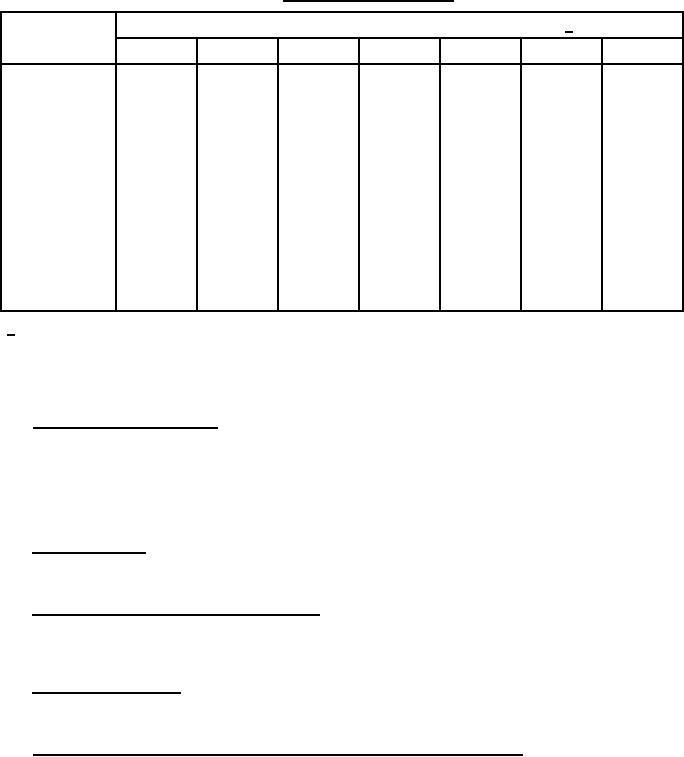

table CI TABLE CI

TABLE CI. C = 0 (zero defect) sampling.

Sample size (number of test specimens to be inspected) 1/

Lot size

Series A

Series D

Series F

Series H

Series J

Series L

Series N

1 to 8

All

All

All

5

3

2

1

9 to 15

All

All

13

5

3

2

1

16 to 25

All

All

13

5

3

2

1

26 to 50

All

32

13

5

5

3

1

51 to 90

50

32

13

7

6

4

2

91 to 150

50

32

13

11

7

5

2

51 to 280

50

32

20

13

10

6

2

281 to 500

50

48

29

16

11

7

3

501 to 1,200

75

73

34

19

15

8

4

1,201 to 3,200

116

73

42

23

18

9

5

1/

If lot size is smaller than sample size test all of the units. Sample size series "A" was identified as "B" in

previous revisions.

C.5

C.5. TEST EQUIPMENT AND INSPECTION FACILITIES

C.5.1

C.5.1 Test equipment and calibration. All tests and measurements for process control, qualification testing,

inspection of product for delivery (in-process and group A), or periodic conformance inspection (group B) shall be

made with capable instruments whose accuracy has been verified. Calibration of measurement, test equipment, and

test standards that control the accuracy of inspection and test equipment and facilities shall be in accordance with

NCSL Z540-1 or equivalent. Calibrated test equipment and test standards shall be controlled, used, and stored in a

manner suitable to protect calibration integrity. Test equipment requiring calibration shall be identified and labeled in

accordance with NCSL Z540-1 or an equivalent system, approved by the qualifying activity.

C.5.2

C.5.2 Inspection facilities. The inspection facility (either the manufacturer's site or a certified suitable laboratory)

used to perform qualification testing and periodic conformance inspection shall be approved by the qualifying activity

for the performance of the tests and inspection requirements of compliant printed wiring boards.

C.5.3

C.5.3 Acquiring activity or manufacturer imposed tests. Acquiring activity or manufacturer imposed tests shall be in

accordance with the requirements specified in the master drawing. If any additional imposed tests detect a problem,

the manufacturer shall submit all panels/printed wiring boards in the lot to those tests to eliminate rejects and shall

take steps to determine and eliminate the cause of failure.

C.5.4

C.5.4 Test method alternatives. Alternate test methods are allowed provided that it is demonstrated to the

qualifying activity that such alternatives in no way relax the requirements of the test method referenced by this

specification (see appendix B).

C.5.5

C.5.5 Procedure in case of test equipment malfunction or inspection/test personnel error. When it has been

established that a improper test is due to test equipment malfunction or inspection/test personnel error, the inspection

facility shall document the results of its investigations and corrective actions, if required, and shall make this

information available to the qualifying activity and the acquiring activity, as applicable.

59

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business