MILPRF50884F

APPENDIX A

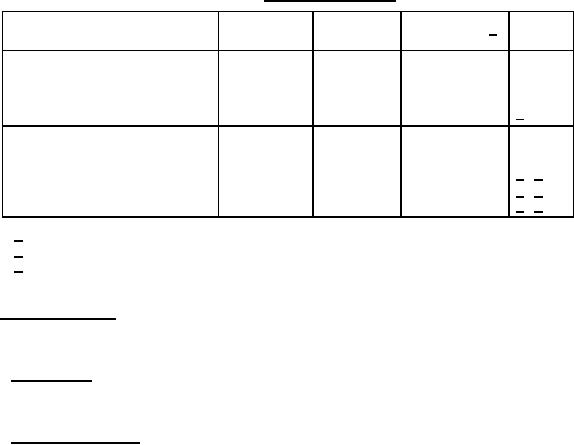

TABLE AVI. Inprocess inspection.

Requirement

Method

Sample size 1/

Inspection

Notes

paragraph

Paragraph

Subgroup 1

Material

See A.4.8.1.8

Ionic contamination (cleanliness)

Plan BN or TL

2/

Subgroup 2

Conductor spacing

Plan BH

2/ 3/

Conductor width

Plan BH

2/ 3/

Conductor pattern imperfections

Plan BH

2/ 3/

1/

2/

The verification shall be performed prior to solder mask or coverlayer application.

3/

The verification shall be performed prior to lamination on each production lot.

A.4.6.2 Group A inspection. Group A inspection shall consist of the inspections specified in table AVII. The

qualified manufacturer shall be responsible for completion of all group A inspections and shall be subject to loss of

qualification for failure not to complete or to have completed all group A test and inspections.

A.4.6.2.1 Inspection lot. A group A inspection lot shall consist of the number of printed wiring boards fabricated

from the same materials, using the same processing procedures, produced under the same conditions within a

maximum period of 1 month and offered for inspection at one time.

A.4.6.2.2 Sampling procedures. Statistical sampling and inspection shall be in accordance with appendix C. For

100 percent inspection, all rejected units (printed wiring boards or panels of printed wiring boards) shall not be

supplied on the contract. All sample units shall be chosen randomly. The following details on panel/test coupon

sampling shall apply:

a.

Non-stressed specimen (as received condition) microsection evaluations (see A.3.7.2.1):

(1) Types 2 and 5: The test specimen shall be test coupon "A". The number of sample units to be

microsectioned shall be based on a statistical sample of panels in the lot in accordance with

appendix C, table CI, series L. The samples for the as-received condition and resistance to soldering

heat testing shall be selected from different panels.

(2) Types 3 and 4: One "A" or "AB-R" test coupon for each panel shall be microsectioned and inspected

(see A.4.6.2.2.d.2). The orientation of the as-received condition microsection shall be orthogonal to the

resistance to soldering heat microsection.

b.

Solderability (see A.3.7.4.9):

(1) For Sequential Electrochemical Reduction Analysis (SERA), samples shall be selected in accordance

with appendix G of MILPRF31032.

(2) For JSTD003 or the solderability test methods of appendix G of MILPRF31032: When test coupon

"S" is the test specimen, the number of sample units to be tested shall be based on a statistical sample

of the number of panels in the lot in accordance with appendix C, table CI, series L. When test coupon

"A" is the test specimen, the number of sample units to be tested shall be based on the same statistical

sample of test coupon "S", but a multiple of 4 shall be applied to the resulting sample size.

39

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business