MILPRF55110G

APPENDIX A

A.4.6

A.4.6 Inspection of product for delivery. Inspection of product for delivery shall consist of in-process and group A

inspection. Except as specified in A.4.7.1.4, delivery of printed wiring boards which have passed in-process and

group A inspection shall not be delayed pending the results of the periodic inspection. Anomalies or defects noted on

sample printed wiring boards or test coupons (or both) defined herein shall be recorded and the proper corrective

action shall be initiated. Manufacturers that are qualified to use contract services (see A.4.5.3.3) are still responsible

for in-process and group A inspections and shall be subject to loss of qualification for failure to complete the

in-process and group A inspections.

A.4.6.1

A.4.6.1 In-process inspection. Each inspection lot of printed wiring boards or panels, as applicable, shall be

inspected in accordance with table AIII. When permanent solder resist is specified (see A.3.1.1), the in-process

inspections specified in subgroups 1, 2, and 3 of table AIII shall be performed prior to solder resist application. Prior

to lamination of type 3 printed wiring boards, the in-process inspections specified in subgroup 2 of table AIII shall be

performed.

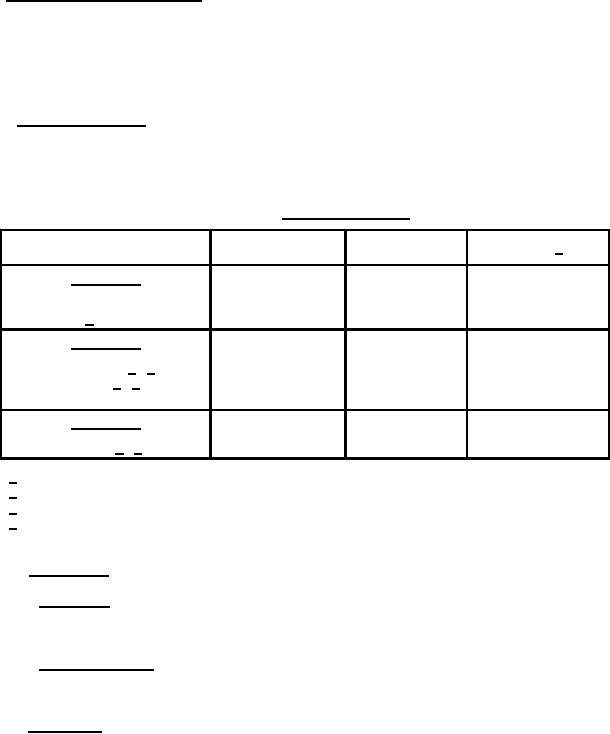

table AIII TABLE AIII

TABLE AIII. In-process inspection.

Requirement

Method

Sample size 1/

Inspection

paragraph

paragraph

Subgroup 1

See A.4.6.1.4

Material

Plan BN or TL

Cleanliness 2/

Subgroup 2

Plan BH

Conductor spacing 2/ 3/

Plan BH

Conductor width 2/ 3/

Plan BH

Conductor pattern imperfections

Subgroup 3

Plan BH

Plating adhesion 2/ 4/

1/

2/

Performed prior to solder resist application.

3/

Performed prior to lamination on each production lot.

4/

A non-reflowed test coupon prior to reflow may be required (see A.6.2).

A.4.6.1.1

A.4.6.1.1 Inspection lot.

A.4.6.1.1.1

A.4.6.1.1.1 Subgroup 1. An inspection lot shall correspond to each production lot or each change of shift of work

force, whichever occurs first. Production lots may be grouped based on same materials, same type or types of

interfacial connections and terminations, and same processing requirements.

A.4.6.1.1.2

A.4.6.1.1.2 Subgroups 2 and 3. An inspection lot shall consist of the number of printed wiring boards fabricated

from the same materials, using the same processing procedures, produced under the same conditions within a

maximum period of 1 month and offered for inspection at one time.

A.4.6.1.2

A.4.6.1.2 Sample size. The number of printed wiring boards or panels to be selected from each inspection lot shall

be in accordance with table AIII.

27

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business